Beer Tap Wall Systems: Installation Maintenance For Breweries and Pubs

Beer Tap Systems Customized for Breweries and Pubs

Our Self-Serve Flight Simulators

Repair, maintenance, and installation services are offered for all of our self-serve beer tap walls. This includes our:

4-Tap Self-Serve Flight Simulator

Using only intelligent technologies, these beer dispenser units are extremely efficient and productive taking your brewery to the next level.

6-Tap Self-Serve Flight Simulator

Each unit has a slim profile allowing for the perfect fit into any space, big or small.

6- Taps & 6- Screens Self-Serve Flight Simulator

Drive meaningful guest experiences, keeping beer flights engaging and memorable while improving your bottom line.

8-Tap Self-Serve Flight Simulator

These mighty units are the perfect balance between fast speed of service and creating that lasting impression that keeps customers returning for more.

Understanding Our Services

Our nationwide services include:

Running a craft beer business is stressful enough—you don’t want to add the worry of maintaining the integrity of your beer lines to the mix. With our state-of-the-art commercial beer tap system, our goal is to make your job easier. That’s why we offer full installation and upkeep of our draft beer systems. To ensure long-term functionality, our end-to-end services encompass everything from expert installation to continuous maintenance.

Draft Beer Tap Wall System Consultation and Design

We understand that your brewery or pub is unique, which is why we prioritize collaboration and customization. During your consultation, we walk you through the difference between long, short, or direct draw installations. We also offer options like self-pour systems with RFID technology for easy, secure access.

Expert Installation

Associated with the Draught Beer Quality Manual published by the Brewers Association, our technicians have helped to develop processes and procedures for the IBDEA (International Beverage Dispensing Equipment Association) Knowledge Center and Draught Academy Classes. This allows them to install custom draft beer systems efficiently, ensuring doors, taps, and kegs are positioned for convenience and functionality.

Staff Training

Our high-tech beer tap wall systems are most effective when your staff is adequately trained, which is why we include comprehensive training services. Misuse and inefficiencies can cause product waste, damage to equipment, and frustration for employees. To prevent these issues, we ensure your team learns how to operate, clean, and troubleshoot your draft beer system, empowering them to manage the self-serve tap wall confidently.

System Repair, Maintenance, and Technical Support

Concerned about handling everything alone after installation? You don’t have to be! To maintain your draft beer tap system in peak condition, we'll schedule regular visits to your brewery or pub for upkeep. Our nationwide team of technicians offers ongoing cleaning, system inspections, and further assistance.

Exceptional Customer Service

Ensuring client satisfaction is our foremost goal. Our wide-ranging services are designed to provide you with a positive experience at every step, giving you confidence that your system will perform effectively. This is supported by expert installation and ongoing maintenance services.

The Benefits of Our Services For Breweries and Pubs

If you own a brewery or pub, we offer more than just the basic draft beer system installation and upkeep. Our state-of-the-art equipment, including our Self-Serve Brewery Flights, is designed specifically with your business in mind. Here’s how:

Maintaining Your Brand

Our self-serve flight simulators help you stand out from the crowd, and our ongoing services ensure you can maintain a high-quality brand. Regular maintenance guarantees consistent performance and top-notch quality. This upkeep protects your brand’s reputation and enhances customer satisfaction, making your brewery or pub the go-to spot for craft beer enthusiasts.

Ensuring Efficient Service

Through regular maintenance of our wall-mounted beer taps, we ensure your day-to-day operations are streamlined. That's because keeping your self-serve systems in peak condition minimizes downtime and optimizes service speed.

Versatile Repairs

With 4-tap, 6-tap, and 8-tap flight simulators, our comprehensive services cater to your specific needs and space constraints. Our expert maintenance team ensures all units are organized and functioning perfectly, regardless of their size and level of customization.

Installation That Optimizes Customer Flow

We take the tasting experience of our draft systems seriously, which is why each self-serve unit is installed with dedicated spaces for flight paddles and glasses. This thoughtful installation elevates the ambiance for a seamless and enjoyable visit.

Frequently Asked Questions:

Draft beer systems are designed to store and dispense beer from kegs, ensuring that it is served fresh and cold at the appropriate pressure and temperature.

Draft beer systems operate using CO2 or nitrogen gas, which maintains the kegs at the brewery-specified pressure and pushes the beer through the lines to the tap for pouring.

Beverage-grade CO2 systems are designed for carbonated beverages such as beers, ciders, seltzers, sparkling wines, and carbonated cocktails from kegs. For still beverages, beverage-grade nitrogen is used, which includes red and white wines, cold brew coffee, and nitro coffees, typically at higher pressures. Nitro stouts usually contain 25% CO2 and 75% nitrogen.

You can adjust the gas and pressure levels in the system to serve both carbonated and non-carbonated drinks based on your needs.

A standard draft beer system consists of keg couplers, beer and gas tubing, primary and secondary gas regulators, beer FOBs, glycol-cooled insulated trunk lines, a glycol power pack, tap towers with taps and drip trays, along with numerous stainless steel fittings and clamps.

The maintenance of a draft beer system includes glycol maintenance on the glycol power pack every six months, routine cleaning and sanitizing of beverage lines, changing vinyl beer lines every 12 to 24 months, regularly disassembling and cleaning taps and keg couplers, inspecting insulated glycol trunk lines for damage, and breaking down and cleaning beer FOBs biannually. Learn more here.

Your draft beer system requires regular cleaning. Draft beer lines should be cleaned every two weeks with a caustic solution, and an acid line cleaning solution should be used twice a year. Proper maintenance of your equipment helps prevent bacteria and mold growth in your cooler. Learn more here.

Implementing draft beer systems brings various advantages, particularly for businesses focused on elevating customer experience. A draft beer system ensures that:

- The optimal temperature is preserved for an ideal pour each time.

- A broad array of beer selections is available on tap to cater to diverse palates.

- Quick and efficient service is optimized during high-demand periods.

- By cutting down on the use of bottles and cans, packaging waste is significantly reduced.

When choosing a draft beer system, consider factors like the size of your venue, the number of beer lines you need, the space available, and your beer storage requirements. Feel free to contact us for more details.

Draft beer systems can also be installed in home bars. They come in various sizes, including straightforward kegerators and custom-built options.

When properly maintained in a draft system, beer can remain fresh for 30 to 60 days, depending on its type and storage conditions.

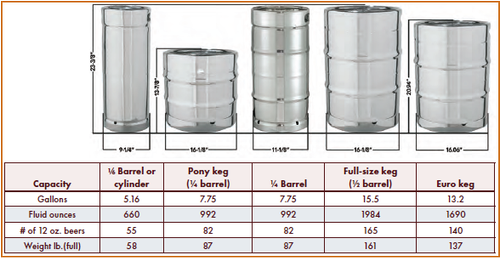

Draft beer systems are compatible with ⅙ barrel kegs, ¼ barrel kegs, full-sized ½ barrel kegs, and Euro kegs.

*Image courtesy of the Brewers Associaton Draught Beer Quality Manual 2019

Nearly all issues with draft beer systems are linked to temperature, mainly concerning keg storage and dispense temperatures. Other factors may include line cleanliness or gas problems. If you’re experiencing issues with your draft beer system, feel free to contact us for assistance.

You should think about upgrading your system if you face frequent malfunctions, inconsistent beer quality, or if it can’t satisfy your business’s volume needs.

The installation cost of a draft beer system depends on several factors, including its complexity, the number of beer lines, and whether it's a direct draw system with taps on the cooler wall or a remote long draw system using glycol-cooled trunk lines that place the taps farther from the cooler. For a free quote, please get in touch with us.

Upgrade Your Brewery or Pub with GS Draft's Unmatched Services

If you want to keep your beer taps flowing long after your initial installation, you're in luck! GS Draft offers unmatched installation, repair, and upkeep services based on the latest technologies. Reach out to GS Draft today for a free consultation. Let's get started on giving your brewery or pub the best beverage services!