How Much Gas is Needed for a Draft Beer System?

Draft System CO2 Tanks

Understanding the role of beverage gas in draft beer systems, is crucial for ensuring the optimal performance and taste quality of dispensed beer, wine, or cocktails.

Carbon Dioxide (CO2) and Nitrogen (N2)

Beverage gases, primarily Carbon Dioxide (CO2) and Nitrogen (N2), play a pivotal role in the carbonation and preservation of various beverages. CO2 is commonly used for carbonated drinks such as beers, ciders, and sparkling wines, providing the fizz that enhances the drinking experience.

Nitrogen, on the other hand, is used for still beverages like wines and cold brew coffee, offering a smoother, creamier texture, especially in nitro coffee and nitro beers.

Blended Gases

Blended gases, combining CO2 and Nitrogen, are for dispensing nitro beers or stouts, and are dispensed using a higher gas pressure, ensuring the signature cascading effect and rich mouthfeel.

How Much Gas is Needed for a Draft Beer System?

Beverage gases, such as carbon dioxide (CO2) and nitrogen (N2), are crucial for carbonating and dispensing drinks in commercial beer tap systems, including in bars, restaurants, and any establishment serving draft beverages. The size of the tanks and the amount of gas they hold can vary widely depending on the needs of the establishment and the specific application. Here's a basic overview:

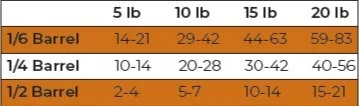

The precise amount of gas needed varies, but a general rule of thumb for a draft beer system is 0.5 lbs per every full-sized half-barrel keg at a pressure of 12-14 PSI. Gas pressures can vary based on the CO2 volume in the keg from the brewer, location elevation, and keg storage temperature. Keep in mind that the yield may be slightly lower if there are any changes or potential leaks in the draft beer system.

It's important to be conservative when estimating how much gas you will need based on the number of kegs you will serve to ensure you don’t accidentally run out of gas during a busy period.

Keg sizes can vary by brewery, and certain beers are often only available in smaller 1/6 Barrels or 1/4 Barrels from smaller Craft Breweries. Generally, you want to purchase the largest keg available for your more popular, faster-moving beers.

**Image courtesy of the Brewers Association Draught Beer Quality Manual 2019

CO2 Tank Sizes and Capacities For Draft Beer

Selecting the perfect CO2 tank size is crucial for anyone any business serving draft beverages on tap. To determine what size tank you need requires you to know how many kegs you plan to serve between refills, and also considering the tank's storage location, and the space it requires.

The size directly impacts the amount of beer you can carbonate and serve, considering both the tank's capacity and the required space. Keeping in mind you will probably need both CO2 and N2 for your Draft Beer System.

CO2 Tank Sizes

CO2 tanks come in various types to meet different needs. For homebrewing, many enthusiasts prefer the smaller 5lb tanks, while commercial settings often require larger sizes, such as the 20lb or 50lb tanks. Aluminum CO2 tanks are popular for smaller cylinders because they are lightweight and easy to transport, making them a convenient choice. On the other hand, steel tanks are the go-to option for larger cylinders of 20lbs and above. Regardless of your specific requirements, there is a CO2 tank perfectly suited to your needs, ensuring convenience and efficiency.

Small: Ideal for kegerators and portable beverage dispensers.

Medium: Used in restaurants and small businesses.

Large: Serves industrial needs where a substantial amount of CO2 is required.

1. Small Cylinders

These tanks are commonly used for small-scale operations or kegerators. They can hold anywhere from 2.5 pounds to 20 pounds of CO2. When it comes to nitrogen, small tanks may have a similar gas capacity, but it's measured differently due to the different properties of nitrogen.

2. Bulk Cylinders/Tanks

These tanks are utilized by larger establishments and are available in a range of sizes, from 20 pounds to over 200 pounds of CO2. Similarly, nitrogen tanks are also available in large sizes designed for commercial use, where a significant amount of gas is needed for nitrogenated beverages.

3. Microbulk and Bulk Systems

For high-volume needs, businesses may use microbulk systems that can hold hundreds to thousands of pounds of gas or bulk storage tanks, often refilled on-site by suppliers.

Types of Beverage Gas and Uses Overview

What types of beverage gas are there, and which beverages are each gas used for?

Beverage Grade CO2

Use CO2 for Beer, Ciders, Seltzers, Sparkling Wines, and Carbonated Cocktails

Beverage Grade Nitrogen

Use Nitrogen for Still Wines, Still Cocktails, Cold Brew Coffee, and Nitro Coffee

Blended Gas (aka Beer Gas)

Use for Nitro Beers/Stouts

Businesses should choose the right size and type of tank based on their specific needs, considering factors like the volume of beverage served, available space, and frequency of delivery or tank exchange. Let GS Draft assist you with all your draft beverage dispensing needs. Call us, and we’ll guide you every step of the way.